Table of Contents

Are you trying to decide between welding vs. dip brazing? Unsure which is better and stronger? Many people end up with the same questions, not to worry you’re not alone.

When you need to join multiple parts together, you need the best option. You also need a bond that is going to be strong. This guide will help you to understand the aluminum dip brazing process and its benefits.

The need to bind two or more parts and pieces together in order to create custom products is more common than you might think. One of the main concerns when joining two parts together is making sure the bond is as strong as the base materials. Aluminum dip brazing is a versatile and economical solution to the need for binding two different parts together to make one cohesive product. Let’s take an in-depth look at aluminum dip brazing and how it can meet your custom metal fabrication needs.

What is Aluminum Dip Brazing?

Aluminum dip brazing is quite a popular, clean and inexpensive option when you compare it to others. It is the process of bonding two or more parts together with a filler metal. The filler metal forms a strong bond in all the joined areas, which are sometimes stronger than the base materials.

Dip brazing is a four-step method. The first is to thoroughly clean the materials that are going to need brazing. This will allow the filler metal to maximize the attachment.

For the second step, all the parts are placed in the final positions. Then you place the filler metal near the joints. Doing this ensures you get the ultimate coverage.

Then the third step is the entire piece is placed into a preheated furnace. It includes all the base materials and the filler metal. Doing this allows for a uniform temperature over the entire piece.

For the last step, you place the whole piece into a salt bath flux for less than two minutes. The time varies for different materials and physical properties. This ensures that the flux surrounds the materials at the same time, which then joins them uniformly.

The final product is set aside to cool. The bonds will be cohesive, clean, and will be very strong. Once it has been fully set, it is then ready for use.

This method is used across many different industries in the fabrication of parts, products, and special equipment. Often times, pieces and parts need to specially made from two or more standard parts. Aluminum dip brazing allows for the creation of either just a one-time specialized piece of equipment or a new custom-made part for the manufacturing of a brand new product.

What is the Process of Aluminum Dip Brazing?

The method of aluminum dip brazing is a four-step process. The first step in the process of aluminum dip brazing is to thoroughly, clean the parts that are to be brazed. This step consists of a deep chemical cleaning to remove all dirt and debris from the manufacturing process. Cleaning is necessary in order to achieve maximum adhesion by the filler metal.

In the second step, the parts are assembled into their final position. The filler metal is then placed as close to the joints as possible, which ensures maximum coverage.

The third step consists of placing the entire assembly with the filler metal in place into a preheated air furnace to achieve a uniform temperature across the assembly.

In the fourth step of the aluminum dip brazing process, the entire assembly is placed in a salt bath which is actually aluminum brazing flux. This step typically takes less than two minutes. The exact amount of time needed varies between different materials and is dependent on the physical properties of the base parts. As the flux surrounds the assembly it comes in contact with all of the internal and external surfaces at the same time. This joins all of the pieces together uniformly.

The final product will need time to cool and set before it is ready for use. Once set, the bonds are clean, cohesive, and high strength.

Benefits of Aluminum Dip Brazing

Aluminum dip brazing offers more benefits than other processes. It is financially a better choice as it has lower tooling, assembly, and material costs. It is also a faster process that lowers labor costs. This is an economical method with lower material, tooling, and assembly costs. Aluminum dip brazing offers EMI shielding, complete coverage, and improved conductivity.

With dip brazing, the finished result doesn’t need extra finishing, unlike other bonding processes. Even if different materials need joining, the end product keeps the integrity of your structure and adds strength.

A brazed joint has a smoother appearance and is stronger, unlike a welded joint. Appearance is an important factor, due to customers looking for a more appealing look. A brazed joint also doesn’t need any of the finishing touches a welded joint needs, this makes it look neater and more uniform.

Aluminum dip brazing can be produced in batches if necessary. The resulting joint is clean and does not require secondary finishing as compared to other bonding methods. Even if the parts are made of different materials, the heat and stress is uniform, resulting in a product with a great deal of strength while keeping the structural integrity of the part.

Common Industries and Situations

Aluminum dip brazing is ideal for a variety of situations. These include parts which need clean joints, bonds between metals and non-metals, parts made of different thicknesses, bonds required over large surface areas, and parts that have finishes which must be preserved.

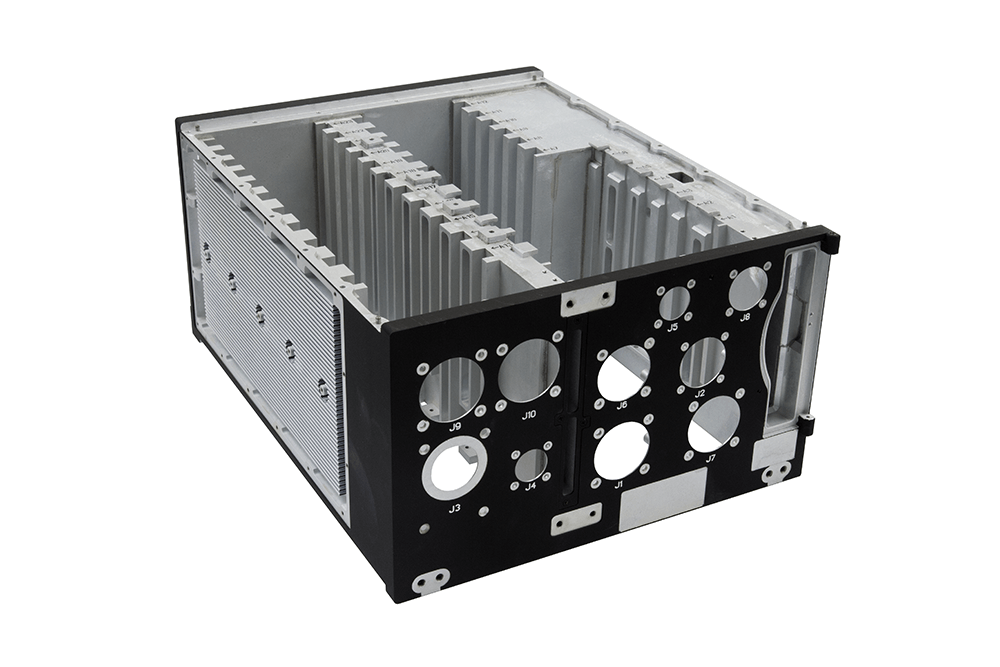

A variety of industries use aluminum dip brazing in order to engineer and produce the highest quality products to meet consumer needs. Common industries include military, medical, aerospace, energy, and electronics. This method may be used to fabricate a part needed to finish a product or as a finished product itself. Consumers expect products made of the highest quality and to the safest standards. Aluminum dip brazing produces strong bonds between base parts which means strong parts and products to meet consumer needs.

Metal Fabrication Services For You

Aluminum dip brazing is often the ideal option for many situations. Some of the situations include bonding metals together, clean joints, bonds over large surface areas, and finishes that need preserving.

We can help you no matter what metal services you need. Whether you’re looking for laser cutting, welding, punching, coating, or painting. Have a look at our blog to see how we can help you.

Why Choose NAMF?

New Age Metal Fabrication (NAMF) is the leader in fabrication. Using cutting edge technology, our experts provide precision products to your exact specifications. Not sure exactly what you need? That’s okay, let our experts help make your vision a reality. Contact NAMF today for more information on our fabrication services including our second to none aluminum dip brazing service. Contact us to help you get started.