In an era where sustainability reigns as a paramount concern, industries worldwide are reevaluating their processes and materials to minimize environmental impact. Among these, the field of metal manufacturing stands out with its innovative approaches towards sustainable fabrication.

One such front-runner is New Age Meal Fabricating Co (NAMF), a company dedicated to revolutionizing metal fabrication while prioritizing sustainability. In this piece, we delve into the depths of the intricacies of sustainable fabrication, exploring its significance, benefits, challenges, and promising future.

Understanding Sustainable Fabrication

Sustainable fabrication encompasses a spectrum of techniques aimed at reducing resource consumption, waste generation, and carbon footprint in metal manufacturing processes. From material selection to production methods, every aspect is meticulously evaluated to ensure minimal environmental harm without compromising quality or efficiency.

Sustainability Principles

- Resource Efficiency

- Material Selection

- Responsible Sourcing

- Lifecycle Approach

Key Practices

- Lean Manufacturing: Streamlining operations to reduce waste and improve efficiency.

- Cleaner Production Techniques: Implementing processes that minimize emissions and pollution.

- Product Design for Sustainability: Designing products with longevity, repairability, and recyclability in mind.

Holistic Perspective

- Environmental Impact

- Social Responsibility

- Economic Viability

The Role of Sustainable Fabrication in Modern Industries

In today’s global landscape, sustainable fabrication serves as a cornerstone for industries striving to meet stringent environmental regulations and consumer demands for eco-conscious products. From automotive to aerospace, manufacturers are increasingly turning to low-impact fabrication methods to align with sustainability goals while maintaining competitiveness in the market. This shift is particularly evident in specialized processes such as vertical milling services and the aluminum dip brazing process.

Competitive Advantage

- Market Differentiation: In today’s eco-conscious market, prioritizing sustainability helps companies stand out, attract environmentally aware customers, and foster brand loyalty. For instance, companies offering custom chassis fabrication with sustainable practices can differentiate themselves from competitors.

- Regulatory Compliance: As governments globally tighten environmental regulations, sustainable fabrication is crucial for meeting compliance standards. This is especially important for processes like chemical film coating, where adherence to environmental regulations is paramount.

Driver of Innovation

- Technological Advancements: Sustainability goals have propelled significant progress in fabrication technologies and materials. Innovations such as 3D printing, advanced recycling, and renewable energy-powered facilities are revolutionizing the industry, enabling more sustainable production. These advancements are particularly beneficial for rapid prototype machining, allowing for more efficient and eco-friendly prototyping processes.

- Collaborative Partnerships: Industry, research, and government collaboration drives eco-friendly fabrication innovation by accelerating technology development and adoption through shared resources and knowledge. This collaboration is crucial for improving processes like the dip brazing process, making them more environmentally friendly and efficient.

Risk Mitigation Strategy

- Supply Chain Resilience: Sustainable fabrication decreases reliance on finite resources, mitigating supply chain disruptions from scarcity or geopolitical issues. This is particularly significant for vertical milling services, which often require specialized materials and equipment.

- Reputation Management: Adopting sustainable fabrication enhances companies’ reputation as environmentally responsible corporate citizens. This is especially valuable for companies offering services like custom chassis fabrication, where clients increasingly prioritize working with environmentally conscious suppliers.

Driver of Long-Term Value

- Cost Savings: Sustainable fabrication delivers substantial long-term savings despite initial investments. For example, optimizing the aluminum dip brazing process for sustainability can lead to reduced energy consumption and material waste, resulting in significant cost reductions over time.

- Market Volatility Resilience: Prioritizing renewability enables companies to adapt to changing market conditions and maintain stability amid economic challenges. This adaptability is crucial for services like rapid prototype machining, where market demands can shift rapidly.

Sustainable Practices in Specialized Processes

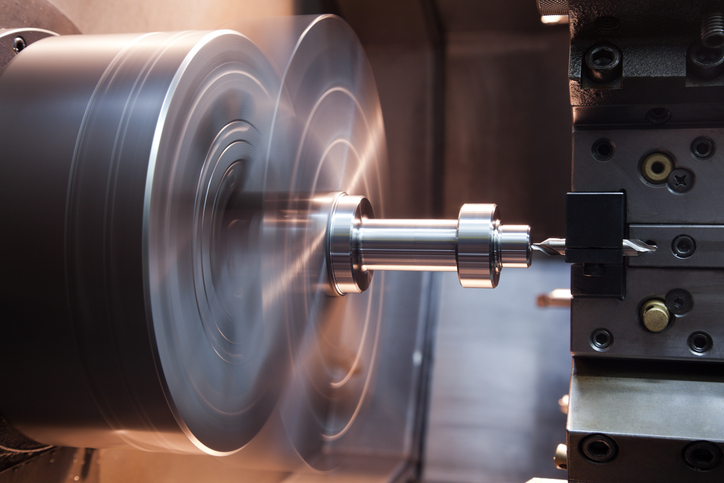

Vertical Milling Services: Implementing sustainable practices in vertical milling services can involve:

- Using energy-efficient machinery

- Optimizing cutting paths to reduce material waste

- Recycling metal chips and coolants

Aluminum Dip Brazing Process: Sustainable improvements in the dip brazing process may include:

- Developing eco-friendly flux materials

- Implementing heat recovery systems to reduce energy consumption

- Recycling and purifying used brazing alloys

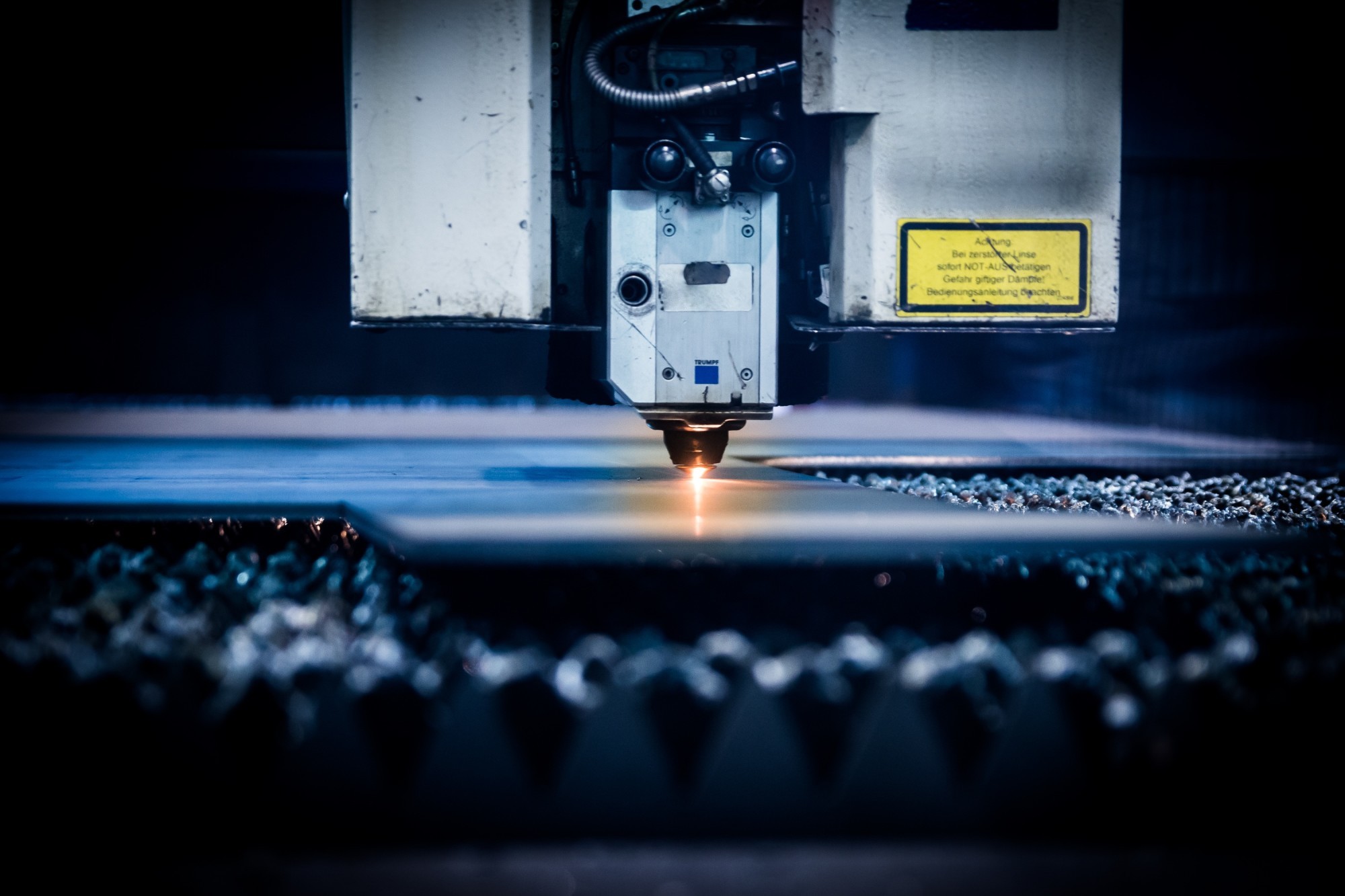

Chemical Film Coating: Sustainability in chemical film coating can be enhanced by:

- Using less toxic, water-based coatings

- Implementing closed-loop systems to minimize chemical waste

- Adopting energy-efficient curing processes

Custom Chassis Fabrication: Sustainable practices in custom chassis fabrication might involve:

- Utilizing recycled metals

- Implementing design optimization to reduce material usage

- Using eco-friendly welding and joining techniques

Rapid Prototype Machining: Sustainability in rapid prototyping can be improved through:

- Adopting additive manufacturing techniques to reduce material waste

- Using biodegradable materials for prototypes when possible

- Implementing energy-efficient machining processes

Benefits of Sustainable Fabrication

The benefits of renewable fabrication extend beyond environmental stewardship. Through maximizing resource utilization and minimizing waste, metal fabrication companies can realize significant cost savings in the long term. Additionally, sustainable fabrication fosters innovation by encouraging the development of alternative materials and processes.

Environmental Conservation

Reduced Carbon Footprint: Sustainable fabrication practices significantly decrease greenhouse gas emissions, contributing to climate change mitigation. This is achieved through:

- Minimizing energy consumption in processes like 5-axis milling

- Utilizing renewable energy sources for powering fabrication facilities

- Implementing energy-efficient technologies in the production of aluminum enclosures

Resource Preservation: Sustainable fabrication plays a crucial role in conserving natural resources by:

- Optimizing material usage, particularly in the production of aluminum coatings

- Promoting recycling of metal scraps and byproducts

- Reducing waste generation through precise manufacturing techniques

Operational Efficiency

Cost Savings: Adopting sustainable practices often leads to substantial reductions in operational costs:

- Lower energy consumption in energy-intensive processes

- Decreased waste management expenses

- Reduced regulatory compliance costs associated with environmental regulations

Process Optimization: Embracing sustainability encourages continuous improvement in manufacturing operations:

- Streamlining production workflows for increased efficiency

- Implementing lean manufacturing principles in metal fabrication

- Enhancing productivity through innovative sustainable technologies

Innovation and Adaptability

Technological Advancements: Sustainable fabrication drives innovation in the industry:

- Development of new, eco-friendly materials for EMI shielding

- Creation of more efficient 5-axis milling techniques that reduce material waste

- Advancement in sustainable aluminum coating processes

Adaptability to Market Trends: Companies that prioritize sustainable fabrication are better positioned for long-term success:

- Meeting growing consumer demand for environmentally responsible products

- Aligning with stringent environmental regulations and standards

- Attracting environmentally conscious clients and partners

Enhanced Product Quality

Sustainable fabrication often leads to improvements in product quality:

- Precision in manufacturing processes, resulting in higher-quality aluminum enclosures

- Development of durable, long-lasting products that reduce the need for frequent replacements

- Improved performance of EMI shielding solutions through innovative, sustainable materials

Competitive Advantage

Metal fabrication companies embracing sustainable practices gain a significant edge in the market:

- Differentiation from competitors through eco-friendly product offerings

- Attraction of environmentally conscious customers and partners

- Potential for entering new markets that prioritize sustainability

Employee Satisfaction and Retention

Sustainable fabrication practices can positively impact the workforce:

- Improved working conditions through cleaner, safer manufacturing processes

- Increased employee pride and engagement in environmentally responsible work

- Attraction and retention of skilled professionals who value sustainability

Brand Reputation and Customer Loyalty

Adopting sustainable fabrication enhances a company’s image:

- Strengthened brand reputation as an environmentally responsible manufacturer

- Increased customer loyalty from environmentally conscious consumers

- Potential for positive media coverage and industry recognition

Challenges in Adopting Sustainable Fabrication

Despite its numerous advantages, the adoption of sustainable fabrication poses several challenges for industries. These factors encompass initial investment costs, reluctance to depart from traditional practices, and the requirement for specialized knowledge and expertise. However, forward-thinking companies like NAMF are proving that the long-term benefits of sustainable fabrication far outweigh these obstacles.

Initial Investment Costs

Transitioning to renewable fabrication often demands substantial upfront investments in new equipment, technology upgrades, and staff training. Many companies, especially those in precision fabricating and full-service manufacturing, hesitate due to perceived short-term financial constraints and uncertainty regarding long-term returns. However, sustainable practices can lead to significant cost savings eventually through reduced energy consumption, waste reduction, and improved resource efficiency.

Resistance to Change

Resistance from stakeholders, including management, employees, and suppliers, can hinder the adoption of sustainable fabrication practices. This resistance often stems from awareness gaps, fear of change, and concerns about workflow disruptions. For instance, companies specializing in rapid prototype machining or military fabrication may worry that new sustainable processes could slow down production or compromise product quality. Overcoming this challenge requires comprehensive education and training programs to demonstrate the benefits of sustainable practices.

Scarce Availability of Sustainable Materials

The limited availability of sustainable materials poses a significant challenge, particularly for industries with specific performance requirements or regulatory standards. Companies engaged in precision fabricating or military fabrication may struggle to find suppliers that offer environmentally friendly alternatives without compromising quality or performance. This scarcity can be particularly problematic for specialized processes like dip brazing, where material properties are crucial.

Lack of Standardization and Certification

The absence of standardized sustainability metrics and certification schemes makes it difficult for companies to benchmark their performance and communicate their sustainability efforts effectively. This challenge is particularly acute in industries like full-service manufacturing, where companies need to demonstrate their commitment to sustainability across various processes. Developing industry-wide standards for sustainable fabrication could help address this issue and provide a clear framework for companies to follow.

Technological Complexity

Implementing sustainable fabrication often requires adopting new, complex technologies. For example, companies involved in rapid prototype machining may need to invest in advanced 3D printing technologies that use sustainable materials. The learning curve associated with these technologies can be steep, requiring significant time and resources for training and integration into existing workflows.

Supply Chain Challenges

Sustainable fabrication extends beyond a company’s immediate operations to encompass its entire supply chain. Ensuring that suppliers adhere to sustainable practices can be challenging, especially for companies with complex supply networks. This is particularly relevant for full-service manufacturing firms that rely on multiple suppliers for different components and materials. Despite these challenges, the adoption of sustainable fabrication practices is becoming increasingly necessary for companies to remain competitive and environmentally responsible.

The Future of Sustainable Fabrication

As technology advances and environmental awareness grows, the future of sustainable fabrication appears promising. Innovations such as additive manufacturing, automation, and advanced materials are poised to reshape the landscape of metal manufacturing.

Companies like NAMF are leading the way in these developments, driving industry-wide transformation towards a more sustainable future.

Advanced Technologies

- Additive Manufacturing (3D Printing): Continued advancements in additive manufacturing technologies will enable more efficient and sustainable fabrication processes, allowing for precise material deposition and reduced waste generation.

- Smart Manufacturing: Integration of IoT devices, data analytics, and automation will optimize resource usage, minimize energy consumption, and improve overall efficiency in sustainable fabrication.

Renewable Energy Integration

- Renewable Energy Adoption: Increased adoption of renewable energy sources, such as solar and wind power, will power sustainable fabrication facilities, reducing reliance on fossil fuels and lowering carbon emissions associated with manufacturing operations.

Materials Innovation

- Bio-based Materials: The development of bio-based materials derived from renewable sources, such as plant-based polymers and bioplastics, will offer sustainable alternatives to conventional materials, reducing environmental impact and promoting resource conservation.

- Recyclable and Biodegradable Materials: Focus on developing recyclable and biodegradable materials will facilitate end-of-life management, enabling efficient recycling and composting processes and minimizing waste disposal.

Regulatory Support and Market Demand

- Regulatory Incentives: Governments will introduce regulatory incentives and mandates to promote sustainable fabrication practices, such as tax incentives for renewable energy investments and subsidies for eco-friendly materials.

- Consumer Awareness and Demand: Increasing consumer awareness and demand for eco-friendly products will incentivize companies to prioritize sustainability in their fabrication processes, driving market transformation and mainstream adoption of sustainable practices.

Conclusion

Sustainable fabrication represents a paradigm shift in the way metals are manufactured, offering a path toward a more sustainable and prosperous future. By embracing resource-efficient practices, businesses can reduce their environmental footprint and gain a competitive edge in the market.

As we look ahead, it is clear that sustainable fabrication will continue to shape the future of metal manufacturing, driving innovation, efficiency, and environmental stewardship. To find out more, contact us today.