Table of Contents

Precision sheet metal fabrication stands at the forefront of modern manufacturing, combining advanced technology with skilled craftsmanship to create flawless components. In industries where perfection is non-negotiable, this specialized process ensures consistent quality and eliminates costly errors that could compromise product integrity.

From aerospace components to medical devices, precision sheet metal work demands expertise in both traditional techniques and cutting-edge manufacturing methods. Through careful material selection, state-of-the-art equipment, and rigorous quality control, this sophisticated fabrication process delivers components that meet the most exacting standards across various industrial applications.

Understanding Precision Sheet Metal Fabrication

Precision sheet metal fabrication represents the pinnacle of manufacturing excellence, where exactitude meets innovation in creating sophisticated metal components. Unlike traditional metal fabrication services, this specialized process demands extraordinary attention to dimensional accuracy and surface quality, particularly in our NJ metal fabrication facility where components often serve critical applications.

The process integrates state-of-the-art technology with expert craftsmanship to produce components that meet exceptionally tight tolerances. This level of precision proves essential in sensitive sectors like electronics, aerospace, automation, and defense, where each component must integrate seamlessly into complex assemblies.

Through advanced custom sheet metal bending techniques and sophisticated sheet metal punching operations, manufacturers can achieve remarkable accuracy while maintaining consistent quality across production runs.

Modern precision sheet metal work relies heavily on computer-controlled machinery, allowing fabricators to maintain exceptional accuracy even with intricate designs. This technological integration, combined with skilled craftsmanship, ensures that each component meets exact specifications while optimizing material usage and reducing waste.

Key principles

Three fundamental principles govern precision sheet metal fabrication: dimensional accuracy, manufacturing consistency, and meticulous attention to detail. Dimensional accuracy ensures that each component adheres precisely to specified measurements, often working within tolerances as tight as ±0.005 inches.

Manufacturing consistency guarantees uniformity across production runs, a critical factor when components must function reliably in assembled systems. Meticulous attention to detail throughout the entire process, from initial design through final inspection, ensures that every aspect of the component meets or exceeds quality standards.

These principles come to life through the combination of:

- Advanced CNC machinery for consistent custom sheet metal bending

- Precision sheet metal punching equipment for accurate hole placement

- Skilled technicians with extensive metal fabrication expertise

- Rigorous quality control procedures at every production stage

- State-of-the-art measurement and inspection tools

Success in precision fabrication requires more than just sophisticated equipment. It demands a comprehensive understanding of material properties, manufacturing processes, and quality control methodologies.

This expertise enables fabricators to anticipate and address potential challenges before they impact production, ensuring consistent quality across every component produced.

Advanced Techniques in Precision Sheet Metal Fabrication

The complexity of precision sheet metal work demands diverse manufacturing approaches, each tailored to specific project requirements. As one of the leading AS9100 certified companies, we implement various sophisticated techniques to ensure exceptional quality and accuracy in every component we produce.

Let’s explore the primary methods that define modern precision fabrication.

Cutting Techniques

Modern precision sheet metal fabrication relies heavily on advanced cutting technologies. Our precision laser cutting services represent the pinnacle of accuracy in metal fabrication. This technique employs focused laser beams to achieve exceptionally tight tolerances and clean edges, particularly crucial for complex geometries and intricate designs.

At our laser cutting NJ facility, we utilize state-of-the-art equipment for aluminum laser cutting and other materials, delivering components with exceptional dimensional accuracy.

The laser cutting process offers several advantages:

- Precision down to ±0.005 inches

- Minimal material distortion

- Superior edge quality

- Complex pattern capability

- Consistent reproducibility

Waterjet cutting provides another high-precision option, using high-pressure water mixed with abrasive materials to cut through metal. This technique proves particularly valuable when thermal distortion must be avoided, as it generates no heat during the cutting process. For thicker materials or larger production runs, plasma cutting offers an efficient alternative, utilizing ionized gas to achieve clean, accurate cuts while maintaining cost-effectiveness.

Forming Techniques

After cutting, precision sheet metal components undergo sophisticated forming processes to achieve their final shape. Computer-controlled press brakes enable precise bending operations, crucial for creating complex components with exact angles and dimensional stability.

This technology proves especially valuable when manufacturing:

- Enclosures for sensitive electronics

- Structural brackets and supports

- Custom panels and covers

- Precision formed components

High-volume production often employs advanced stamping techniques, utilizing precision-engineered dies and sophisticated presses to ensure consistent quality across large production runs.

For more complex geometries, deep drawing processes allow for the creation of deeper components while maintaining tight tolerances throughout the forming operation.

Joining Techniques

The final assembly of precision sheet metal components demands exacting standards in joining operations. Modern welding techniques, including precision TIG and laser welding, create strong, clean joints while maintaining dimensional accuracy.

These advanced processes ensure:

- Minimal heat distortion

- Consistent weld quality

- Superior joint strength

- Clean, professional appearance

For applications requiring mechanical fastening, precision riveting provides a reliable joining method, particularly crucial in aerospace and defense applications where both strength and accuracy are non-negotiable.

Alternative joining methods, such as advanced adhesive bonding, offer solutions for applications where traditional welding might compromise component integrity or appearance.

Advanced Tools and Equipment in Modern Fabrication

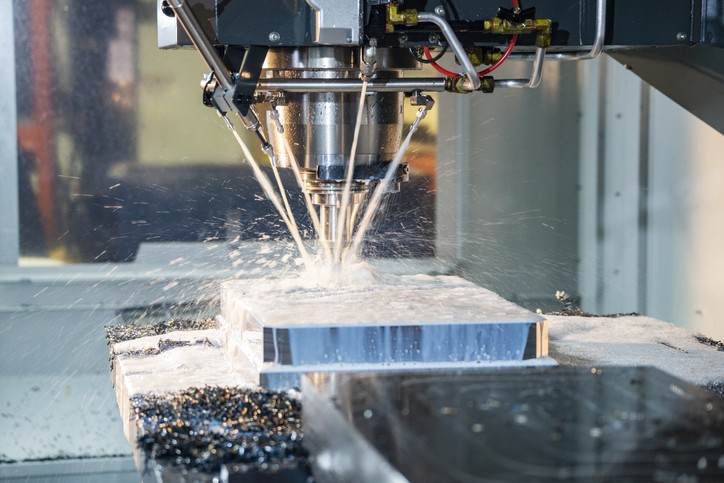

Precision sheet metal fabrication demands sophisticated equipment that combines speed with unwavering accuracy. As manufacturing technology evolves, the integration of advanced machinery and measurement systems becomes increasingly crucial for maintaining exceptional quality standards across all production phases.

Modern Machinery and Automation

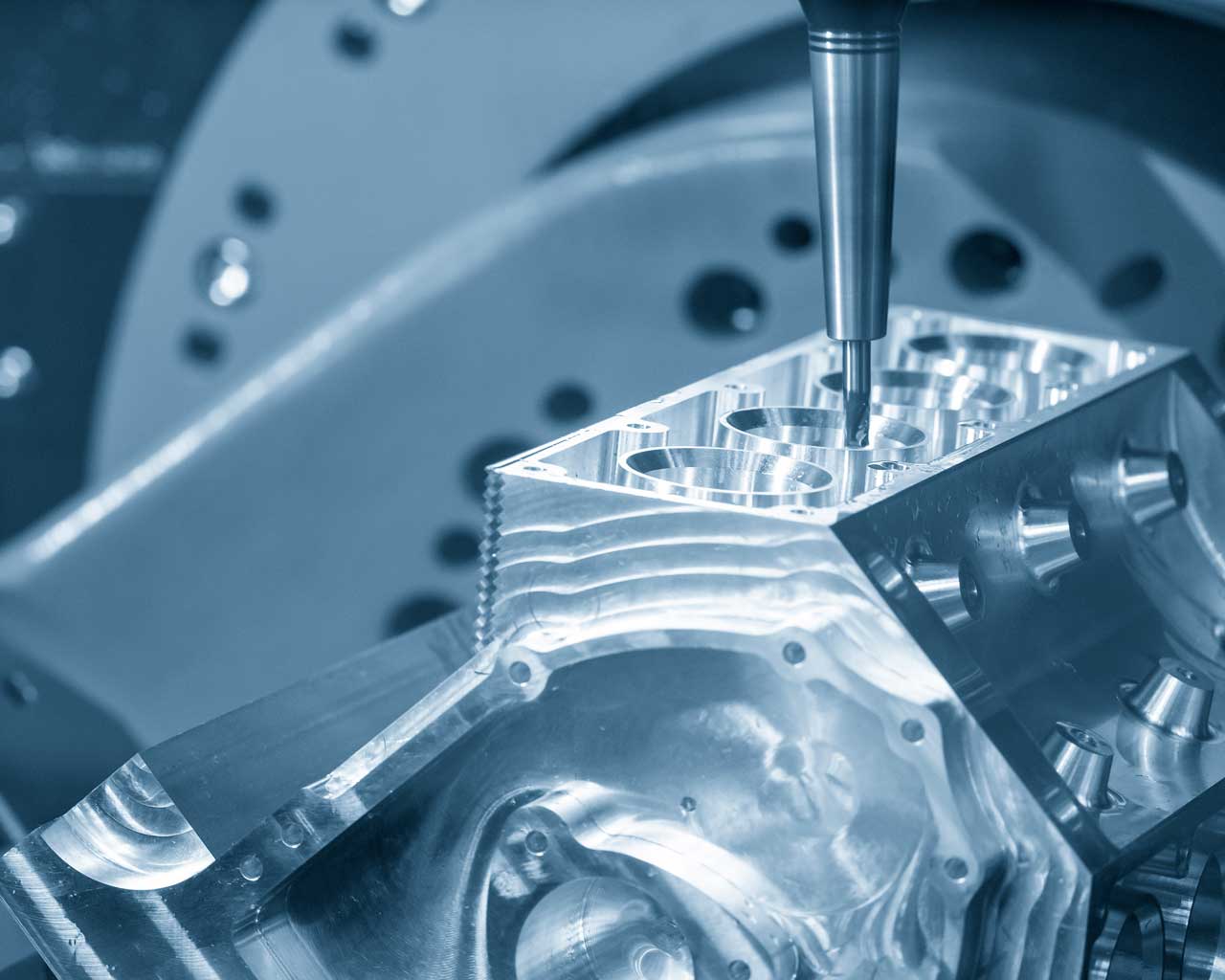

At the heart of contemporary precision fabrication lies Computer Numerical Control (CNC) technology. Beyond traditional high volume CNC machining, these advanced systems incorporate specialized tools for sheet metal processing, ensuring exact specifications for every component.

The integration of automated systems has revolutionized production capabilities, enabling:

- Consistent accuracy across large production runs

- Reduced human error in complex operations

- Enhanced production efficiency

- Superior surface finish quality

- Precise repeatability in manufacturing

Our custom CNC milling capabilities complement precision sheet metal operations, allowing for comprehensive manufacturing solutions within tight tolerances. When combined with CNC rapid prototyping services, this technology enables quick iteration and validation of designs before full production begins.

The automation revolution extends beyond basic cutting operations to include:

- Automated material handling systems

- Robotic welding cells

- Programmed bend sequences

- Integrated quality control stations

- Smart tool changing systems

Measurement and Quality Control Systems

Maintaining precision in sheet metal fabrication requires sophisticated measurement and inspection protocols. Our quality control process employs various advanced tools and technologies:

Digital Measurement Systems:

- High-precision digital calipers (accuracy to ±0.001″)

- Electronic micrometers for thickness validation

- Laser measurement systems for dimensional verification

- Digital height gauges for vertical measurements

- Surface roughness testers for finish quality

Advanced Inspection Equipment:

Coordinate Measuring Machines (CMMs) represent the gold standard in precision measurement, offering:

- Three-dimensional measurement capability

- Automated inspection sequences

- Real-time comparison to CAD models

- Detailed inspection reports

- Non-contact measurement options

These sophisticated measurement systems integrate with our quality control processes to ensure:

- Immediate detection of deviations

- Comprehensive documentation of quality metrics

- Traceability throughout production

- Consistent compliance with specifications

- Proactive quality management

Our investment in advanced measurement technology enables us to maintain exceptional accuracy throughout the fabrication process, from initial prototyping through full production runs. This comprehensive approach to quality control ensures that every component meets or exceeds specified tolerances, supporting critical applications across various industries.

Industrial Applications and Precision Manufacturing

Precision sheet metal fabrication serves as a cornerstone technology across numerous industries where exacting standards are non-negotiable. The versatility and accuracy of modern fabrication techniques make them essential for creating components that meet rigorous specifications in various critical applications.

Aerospace and Defense Applications

Aerospace sheet metal fabrication demands unprecedented precision and reliability. In this sector, components must not only meet strict dimensional tolerances but also achieve optimal weight-to-strength ratios.

Critical applications include:

- Structural support brackets

- Navigation system housings

- Control panel enclosures

- Environmental protection shields

- Thermal management components

In military fabrication, the demands become even more stringent. Military enclosures and components must withstand extreme conditions while maintaining perfect functionality.

These applications require:

- Enhanced durability specifications

- Electromagnetic interference protection

- Environmental sealing capabilities

- Advanced surface finishing

- Precise assembly tolerances

Automotive Innovation

The automotive industry relies heavily on precision sheet metal components throughout vehicle assembly. From structural elements to aesthetic features, each component demands exact specifications for:

- Body panels and structural supports

- Engine compartment components

- Interior framework elements

- Safety system housings

- Thermal management systems

Electronics and Technology

The electronics sector presents unique challenges in precision fabrication, particularly in creating aluminum enclosures for electronics.

These components must provide:

- Precise fit for internal components

- Effective thermal management

- Electromagnetic shielding

- Aesthetic appeal

- Cost-effective production

Modern electronics enclosures require increasingly complex designs to accommodate:

- Advanced cooling systems

- Multiple interface points

- Cable management features

- Security features

- Modular expansion capabilities

Custom and Prototype Development

Beyond standard production, precision sheet metal fabrication excels in creating custom solutions and prototypes.

This versatility enables:

- Rapid prototype development

- Custom design validation

- Small-batch production runs

- Design optimization

- Proof-of-concept models

Each application demonstrates the crucial role of precision fabrication in modern manufacturing, where tight tolerances and reliable performance are essential. Through advanced techniques and rigorous quality control, manufacturers can meet the diverse needs of these demanding industries while maintaining consistency and excellence in every component produced.

Strategic Advantages in Modern Fabrication

While precision sheet metal fabrication requires sophisticated equipment and skilled expertise, the advantages it offers make it an invaluable investment for any metal fabrication company.

As a leading precision fabrication group, we understand how these benefits directly impact both manufacturing efficiency and product quality.

Superior Quality and Reliability

In fabrication and manufacturing, quality consistency defines success. Advanced precision techniques ensure:

- Exceptional dimensional accuracy across production runs

- Consistent material properties and performance

- Superior surface finish quality

- Enhanced structural integrity

- Reliable component integration

Our commitment to precision extends beyond basic manufacturing to custom chassis fabrication and complex assemblies, where accuracy directly impacts system performance. Through rigorous quality control and advanced processing techniques, we consistently achieve:

- Tolerances within ±0.005 inches

- Superior weld integrity

- Precise bend angles

- Consistent material properties

- Exceptional surface finishes

Cost-Effective Production Solutions

While precision sheet metal operations may involve higher initial investment, they ultimately deliver significant cost advantages:

Material Optimization

- Reduced waste through precise cutting patterns

- Optimized material utilization

- Decreased scrap rates

- Lower material handling costs

- Efficient inventory management

Production Efficiency:

- Minimized rework requirements

- Reduced quality control rejections

- Streamlined assembly processes

- Decreased labor costs

- Improved production planning

Enhanced Speed and Adaptability

Modern precision fabrication combines rapid production capabilities with uncompromising accuracy. This balance offers several strategic advantages:

Production Advantages:

- Faster turnaround times

- Consistent quality at higher volumes

- Reduced setup times

- Efficient batch processing

- Flexible production scheduling

Design Flexibility:

- Quick prototype development

- Easy design modifications

- Scalable production options

- Custom solution capability

- Rapid iteration potential

The integration of advanced manufacturing technologies enables:

- Streamlined workflow management

- Reduced lead times

- Improved quality control

- Enhanced production planning

- Greater design freedom

This comprehensive approach to precision manufacturing ensures that each component meets exact specifications and delivers value through improved efficiency, reduced waste, and superior quality. Through continuous investment in technology and expertise, we maintain our position as an industry leader in precision sheet metal fabrication.

Conclusion

The evolution of precision sheet metal fabrication continues to shape the future of modern manufacturing, setting new standards for quality and innovation across industries.

Through advanced technology and expert craftsmanship, leading sheet metal fabrication NJ facilities deliver components that consistently meet the most demanding specifications. As industries advance and tolerances become increasingly stringent, the role of precision fabrication grows ever more crucial in ensuring product reliability and performance.

Whether developing critical aerospace components or creating custom solutions for emerging technologies, precision sheet metal work remains fundamental to manufacturing excellence.

The combination of cutting-edge equipment, skilled expertise, and rigorous quality control ensures that each component not only meets but exceeds industry standards. For projects demanding the highest levels of precision and reliability, working with experienced fabrication specialists helps transform innovative designs into reality.