The value-added services the New Age Companies provide our customers are reflected in the specialized work we do. This work requires careful engineering and precise manufacturing. The products highlighted below are indicative of the scope of our capabilities and the top-quality product you can expect from us.

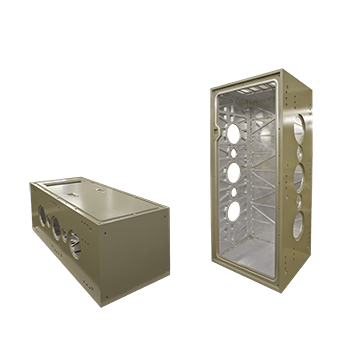

Integrated Maritime Systems Weldment

This Integrated Maritime Systems Weldment called upon all New Age Metal Fabrication’s resources. The finished Weldment stands roughly 65” tall, 30” wide, and 25” deep. The finished product weighs 350 pounds.

The capabilities and processes we used on this Weldment include:

- CNC Machining

- Welding and Inspection IAW MIL-DTIL-D1.2

- Mechanical Assembly and Fixturing

- Chemical Conversion Coating IAW MIL-DTL-5541

- CARC Finishing

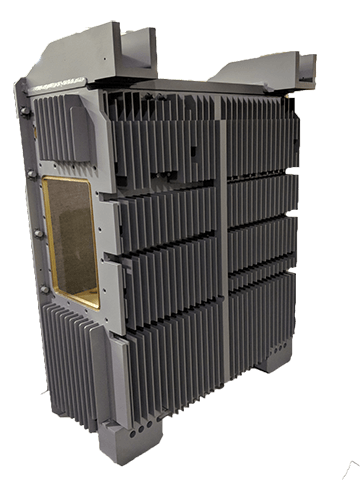

Brazed Housing Subassembly

This Dip-Brazed Housing Subassembly exemplifies our product expertise. The body of the chassis is constructed of 6061 with 0.008” fin stock.

The overall dimensions of the chassis are 15.570” long by 12.631” wide by 7.527” tall with true dimension tolerances of 0.003”. Flatness tolerances were held to 0.01” with close work tolerances as tight as ±0.002”. Dimensional inspection was performed with precision CMM equipment.

Most of our services were incorporated into the manufacturing of this Subassembly:

- CNC Machining

- Assembly

- Welding

- Dip Brazing

- Heat Treating

- Specially Designed Masking

- Engraving

- Chemical Conversion Coating

- CARC Finishing

- Hardware Installation

- Silk Screening, Marking, and Engraving Filling

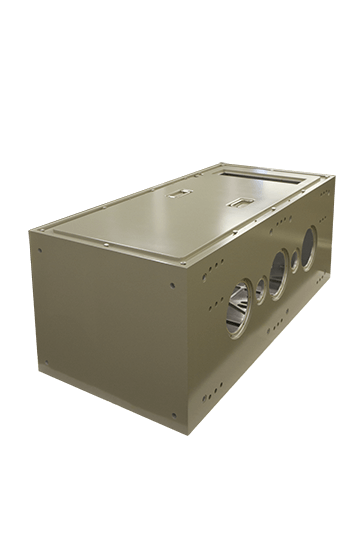

Power Enclosure

This Power Enclosure demonstrates the integrated services offered by New Age Metal Fabricating and New Age Precision Manufacturing. Each of its 14 components are machined either at New Age Metal Fabricating or New Age Precision Manufacturing. The pre-machined components weigh approximately 150 pounds. The finished brazed assembly weighs approximately 80 pounds, with final dimensions of 28” tall by 22” wide and 11” deep.

The components are assembled, dip brazed, and welded at New Age Precision Manufacturing. The final product is then heat treated to T6.

Most of our services were incorporated into the manufacturing of this Enclosure:

- CNC Machining

- Assembly

- Welding

- Dip Brazing

- Heat Treating

- Specially Designed Masking

- Engraving

- Chemical Conversion Coating

- CARC Finishing

- Hardware Installation

- Silk Screening, Marking, and Engraving Filling