Table of Contents

Precision and reliability are paramount in today’s rapidly evolving military and aerospace manufacturing industries. As a result, CNC aluminum machining has emerged as a vital process while meeting the stringent demands of these sectors.

Aluminum products are a vital aspect of the aerospace industry and are widely used in military applications. Precision machining has played a critical role in technological development and deployment throughout many sectors, delivering finished products that must meet exacting standards. This article will explore why CNC machining offers superior benefits for both military and aerospace applications and why finding the right metal fabricating company is crucial to success.

New Age Metal Fabricating’s (NAMF) CNC Aluminum Machining offers high accuracy and precision, quick turnaround times, and the ability to produce complex shapes and designs. CNC Aluminum Machining has many military applications and offers several advantages over other forms of machining.

Military applications that require CNC Aluminum Machining include the production of aircraft parts, weapon systems, and communication equipment. These parts must meet strict standards and specifications to ensure they function correctly and can withstand harsh environments, including battle conditions. CNC Aluminum Machining allows manufacturers to produce parts that meet these standards consistently.

Aerospace applications leave no room for error because any deviation from the required measurements can compromise the safety of the aircraft.

What is CNC Machining?

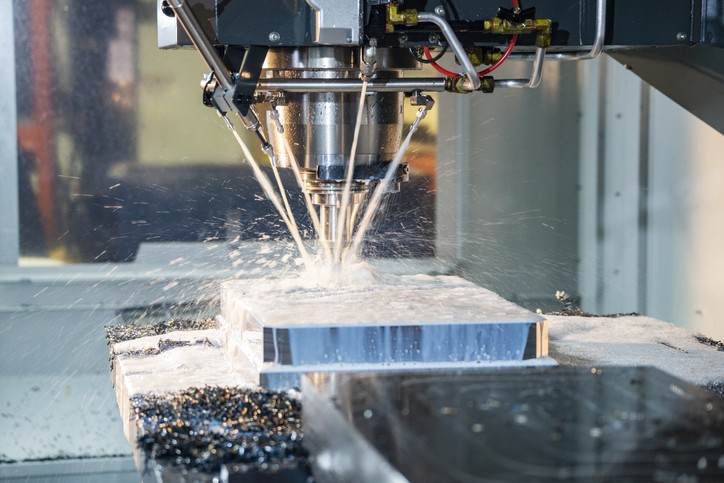

CNC (Computer Numerical Control) aluminum machining uses computer-controlled machines to precisely shape and fabricate aluminum components. This advanced process leverages state-of-the-art software and machinery to translate intricate design specifications into tangible products. With its ability to achieve tight tolerances and complex geometries, CNC aluminum machining ensures the production of high-quality components that meet rigorous military and aerospace standards.

Why Choose CNC Machining Over Manual?

CNC machining has revolutionized the manufacturing and engineering industries with its precision, cutting, automation, and technology. CNC machining has become the preferred manufacturing method for most industries in recent years due to its advantages over manual machining services. While manual machining can produce great results in the hands of a skilled technician, manual machining lacks the consistency that computer-controlled means provide.

Precision in CNC machining refers to a machine’s ability to produce accurate and consistent results. It achieves this through the use of computer-controlled machines that follow pre-programmed instructions. This level of precision is crucial in the manufacturing and engineering industries because it ensures that parts and components are produced to exact parameters.

Once a sequence goes into the computer, the CNC process can produce dozens, hundreds, or thousands of parts cut to the same specs with no variance or margin of error. In addition, this programming sequence can be reused whenever needed, and the resultant parts will always meet the original specifications. CNC machines with high precision and accuracy include milling machines, lathes, and grinders. With these options, we produce various aluminum parts and components with high accuracy, excellent efficiency, and desirable cost-to-benefit ratios.

The Unique Advantages of CNC Machining

CNC machining allows manufacturers such as NAMF to produce parts with tolerances as low as a few microns. This level of precision is necessary for the military and aerospace sectors, where the smallest error can seriously affect the finished product.

Even better, CNC Aluminum Machining offers quick turnaround times. Computer-controlled machines can work continuously, producing parts around the clock in ways human workers can’t. As a result, manufacturers can produce large quantities of parts quickly, reducing lead times and improving efficiency.

Lastly, CNC Aluminum Machining can easily produce complex shapes and designs. CNC machines can move along multiple axes simultaneously, quickly creating intricate designs and shapes.

Special Applications in Aerospace and Military

CNC aluminum machining is essential for meeting the demanding requirements of the military and aerospace sectors. In addition, its versatility and ability to achieve tight tolerances make it indispensable for diverse applications.

CNC-machined aluminum components find their way into various defense equipment, including weapon systems, armored vehicles, communication devices, and surveillance systems. The exceptional precision and reliability of CNC machining ensure optimal performance, durability, and mission success in the defense sector. This is particularly useful in military applications where parts must fit into tight spaces or have unique shapes and requirements.

CNC machining enables the production of critical aircraft parts, such as engine components, landing gear parts, structural elements, and avionics housings. They also constitute critical components for satellite and spacecraft manufacturing, from satellite frames and antennae to propulsion system components. The lightweight nature of aluminum and its excellent strength-to-weight ratio makes it an ideal choice for these applications.

The New Age Metal Fabrication Advantage

The Tri-State Area, consisting of New York, New Jersey, and Connecticut, is a central hub for manufacturing and engineering. Choosing a local service provider offers several benefits, including reduced lead times, lower transportation costs, and easier communication.

New Age Metal Fabrication (NAMF) is a leading provider of CNC aluminum machining services in the Tri-State area. We consistently stand at the forefront of this cutting-edge technology. NAMF stands out as a trusted and innovative industry leader.

Cutting-Edge Technology

NAMF invests in state-of-the-art CNC machines, software, and inspection equipment to ensure the highest quality and precision for every project. In addition, our commitment to embracing the latest advancements in the field positions us as a forward-thinking industry leader.

Expertise and Experience

With years of experience in the military and aerospace manufacturing industry, NAMF has accumulated a wealth of knowledge and expertise. Our skilled engineers and technicians possess a deep understanding of military specifications and regulations, guaranteeing compliance and adherence to the highest standards.

Collaborative Approach

NAMF values collaboration and open communication with our clients. We work closely with customers from initial design to final production to meet all requirements and specifications. NAMF’s dedication to customer satisfaction sets us apart in the industry.

Quality Assurance

At NAMF, quality is paramount. We follow rigorous quality control processes at every stage of CNC aluminum machining, utilizing advanced inspection techniques to verify accuracy and compliance. This commitment to excellence ensures that customers receive exceptional quality and performance.

Call NAMF

When you need high-quality CNC machining for precision aluminum manufacturing in the Tri-State area, call New Age Metal Fabricators. We offer quick turnaround, fair pricing, and free quotes for any project. Contact us today!