With the increase in customized goods, the need to join two or more parts together to create custom products has become quite popular. When joining the parts, you should ensure the bond is stronger than the base materials to make high-quality, durable products.

The dip brazing procedure allows the joining of aluminum components to create strong, leak-proof, and conductive joints. Unlike conventional welded joints, dip-brazed joints are durable to minimize distortion and resist shock.

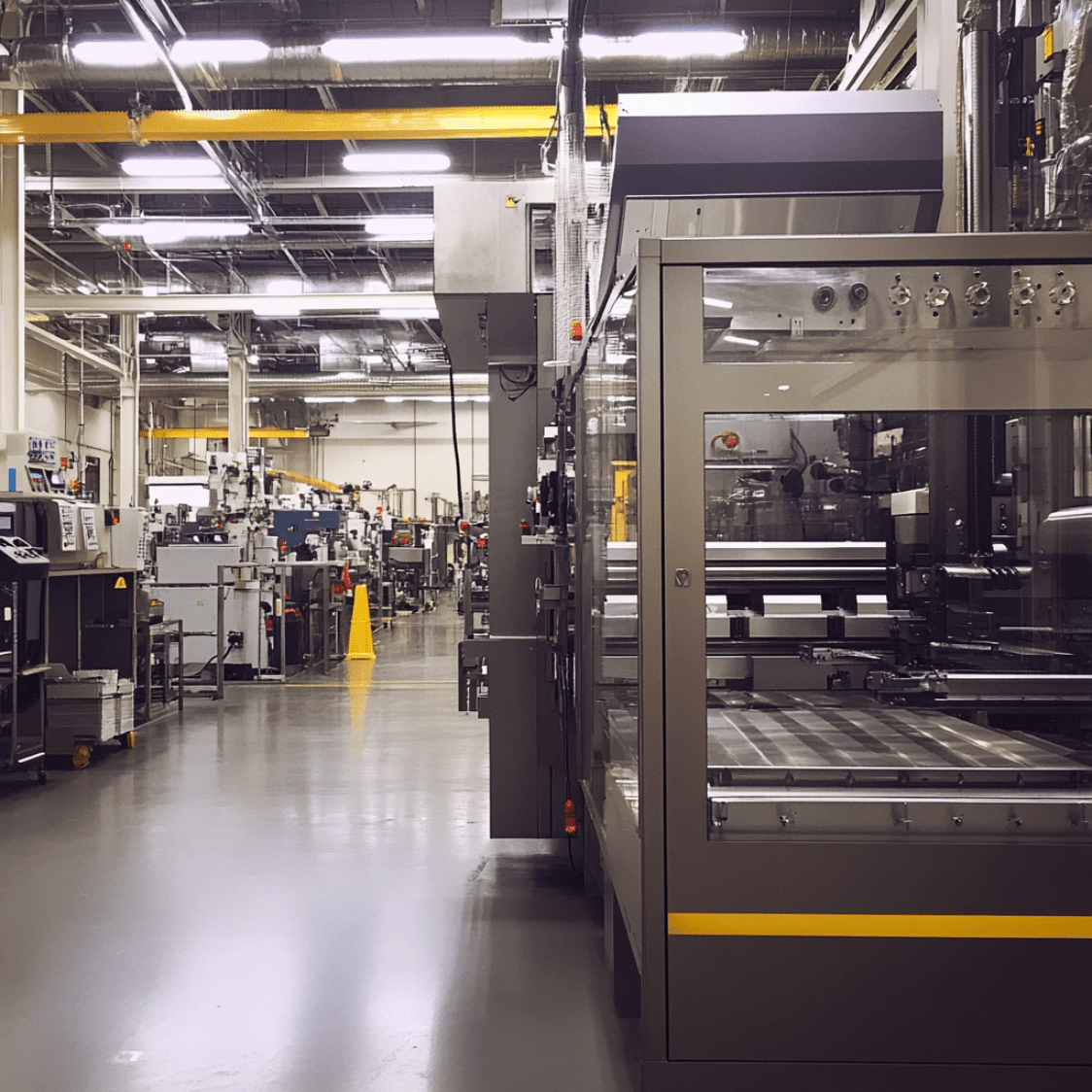

At NAMF, we specialize in aluminum dip brazed assemblies for a wide variety of industries, including military, medical, aerospace, energy, and more.