Leaders in Military Grade CNC Milling

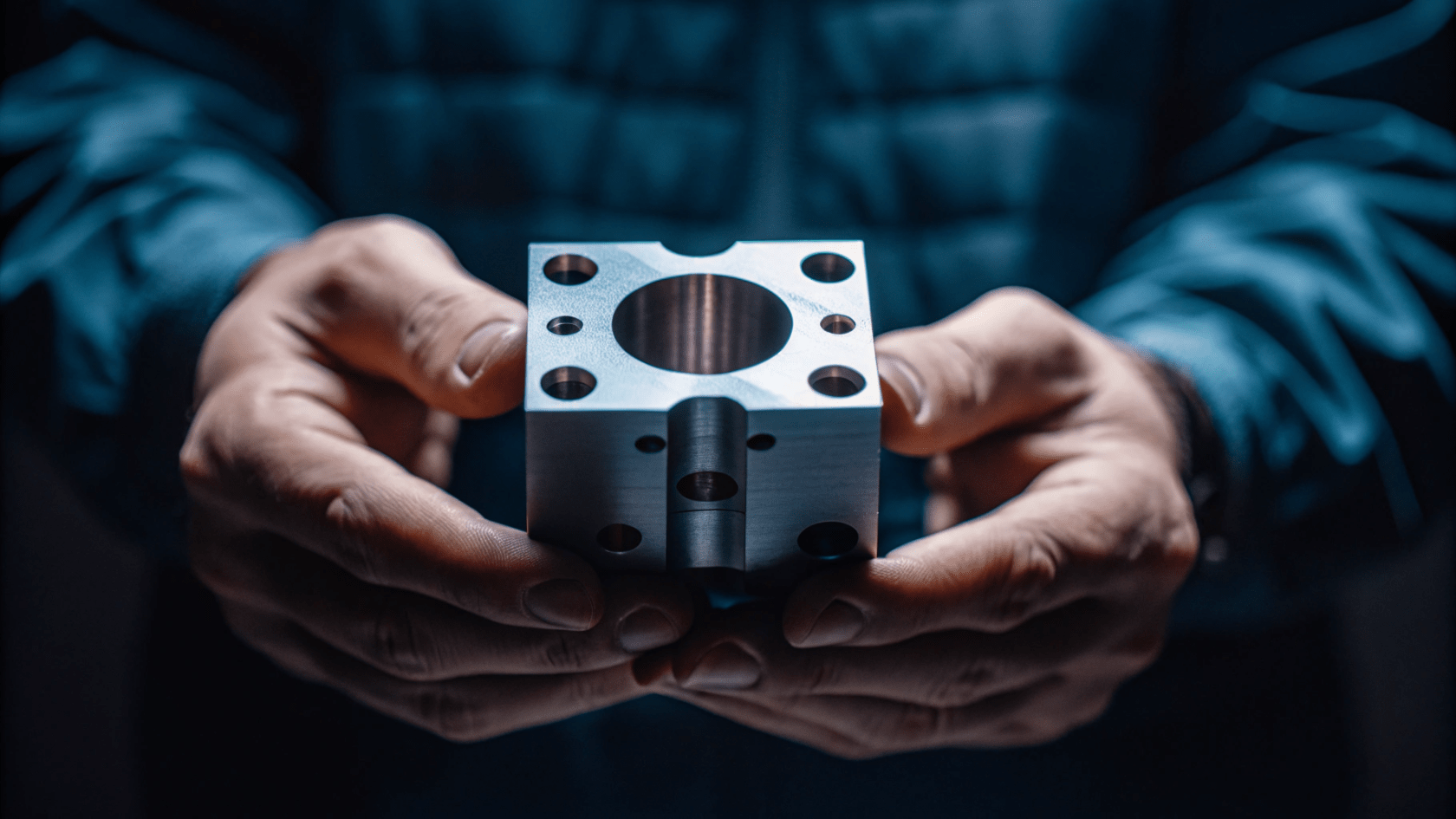

As a business in the military, aeronautics, or engineering industries, your manufacturing risks and requirements are higher than most other businesses.

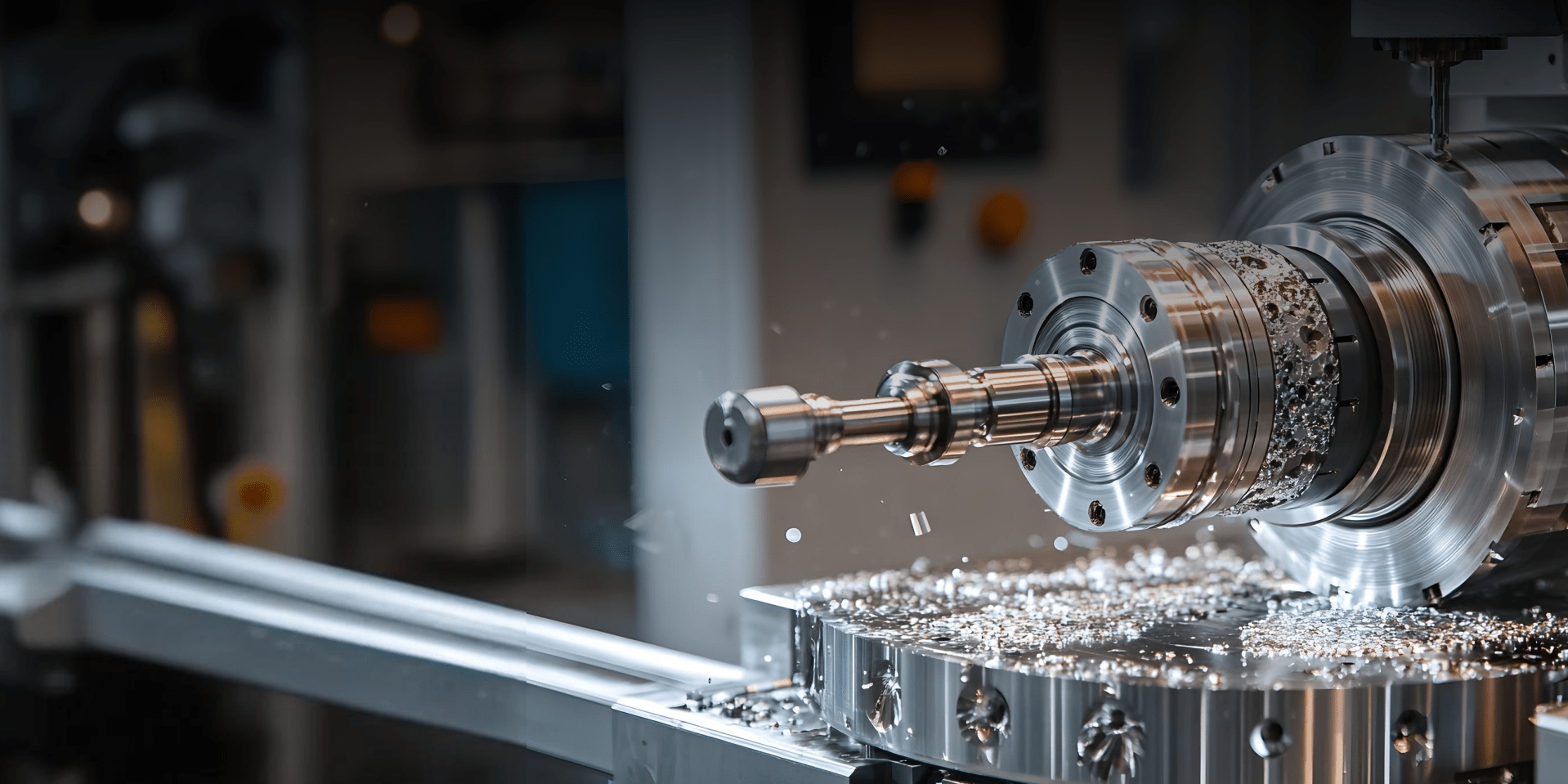

Fortunately, that’s where New Age Metal Fabricating and New Age Precision Manufacturing can help. With access to the industry’s leading technology resources and expertise, we offer the most precise CNC vertical, horizontal, and 5-axis milling available for defense and aerospace.