CNC Milling Machines

The most common type of CNC machine is a milling machine. Milling machines can be further categorized based on their components and functions. These can include horizontal or vertical milling machines, bed mills, turret mills, traveling or double column mills, C-frames, drill-and-tap mills, Double Spindles, etc.

One of the things that differentiate CNC machine types from one another is the number of axes they use and how they use them. For example, the term “5 axis milling” refers to the use of a CNC machine that either simultaneously moves along 5 axes itself, or moves the part being milled along 5 axes simultaneously. Doing so allows machinists to create more intricate parts or designs with minimal additional processing.

There are 3 planes that a machine like this can move along linearly called the X, Y, and Z axes. The additional 2 axes are added from the machine’s rotational movement along any two of these planes. Employing various axes configurations can help specify the type of milling being done and allows for different types of operations to be performed. For example, these could include head-to-head, head-to-table, or table-to-table.

The three potential rotational axes that 5 axis milling can employ are called the A, B, and C axes (corresponding in order to the X, Y, and Z axes). The combination of which two rotational axes are employed can further narrow down the type of milling. Double swivel head means A and C are both being used by a rotating swivel head. Drop swivel head means that the swivel head is using B and C. A double swivel table means that the table is using A and C. Drop swivel table means the table is using B and C. One swing and one rotation means that the swivel head is using one axis and the table is using the other.

The Benefits of 5 Axis Milling

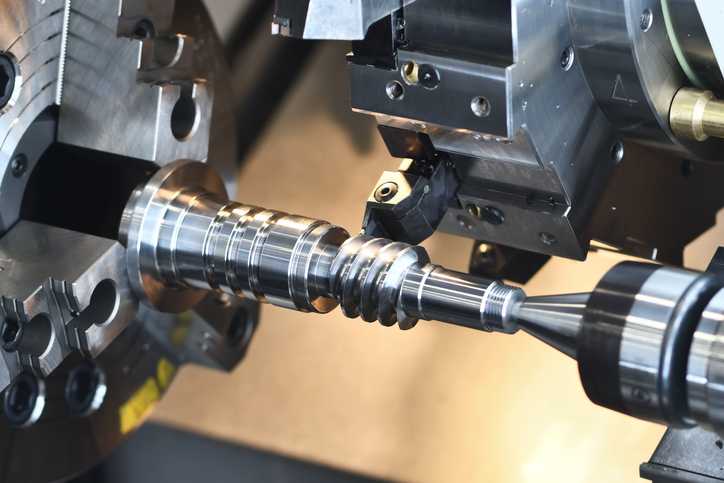

Machinists most commonly use 5 axis milling for more complex parts like precision aerospace parts, complex automotive parts (which often have a very tight tolerance), general industrial parts, and more. The most common materials you’ll see used for these things include aluminum, plastics, stainless steel, titanium, tungsten, and alloys.

So why are these things done with this type of milling, as opposed to other methods? Simply put, 5 axis milling offers a wider range of functions with fewer safety hazards compared to 3 axis milling, and allows for much more precision than 3d printing.

The two additional axes of motion allow for part intricacy that is not available with any other kind of milling or machining. To even try to achieve the same results without 5 axis milling would require machine shops to use more tooling, equipment, and machines on a single part, rather than using one to do the bulk of it. Even if you do use the additional equipment, this creates more opportunities for error and likely won’t achieve the same quality in the end anyway.

Often in machine shops, one person specializes in one or two machines on the floor at a time. This means that using a 5 axis machine and getting the majority of the work done with one machine requires less employee labor. Not only does this increase efficiency (as the other machines can run other parts at the same time), but it also means you can lower labor costs.

In addition, 5 axis machines vibrate a lot less than other milling equipment, which means that they can achieve a clean, smooth coat that wouldn’t be possible for them. Not to mention that 5 axis milling produces results faster than 3- or 4-axis milling would, meaning you can get more done in a day.

Using one machine to create a part that would otherwise need more equipment means that you wouldn’t need as many machines on your shop floor, thus allowing for more efficient use of floor space. 5 axis milling machines also have a relatively simple setup, which means there’s a decreased risk of human error. 5 axis machines are built to include better features, as well, including superior collision avoidance, incorporated hole drilling capabilities, and reduced wearing on tools.

5 axis milling allows machines to operate on all sides of the workpiece without requiring manual rotation. 5 axis machines can also be used with a broader range of tools and inserts, making them far more versatile than other machine types.

5 Axis Milling at NAMF

New Age Metal Fabricating (NAMF for short) is a company founded in 1979 whose goal was to have only the highest quality standards when it came to manufacturing. We use only the best, cutting-edge techniques and technologies for our jobs, which is probably what made us one of today’s leading full-service metal fabricators in the Defense and aerospace fields. NAMF is ISO/AS and NADCAP certified and would be more than happy to work with you, contact us today.