Table of Contents

In precision manufacturing, understanding the differences between 3 axis vs. 5 axis milling is crucial for achieving optimal results in your projects. Whether you’re manufacturing military enclosures or need custom CNC milling for complex components, choosing the right milling process can significantly impact your project’s success.

Understanding the Basics

Milling technology has evolved significantly, offering manufacturers various options for different applications. While both 3-axis and 5-axis milling serve essential roles in modern manufacturing, each brings distinct advantages and limitations that can affect your project’s outcome, timeline, and budget.

Overview of 3 Axis Milling

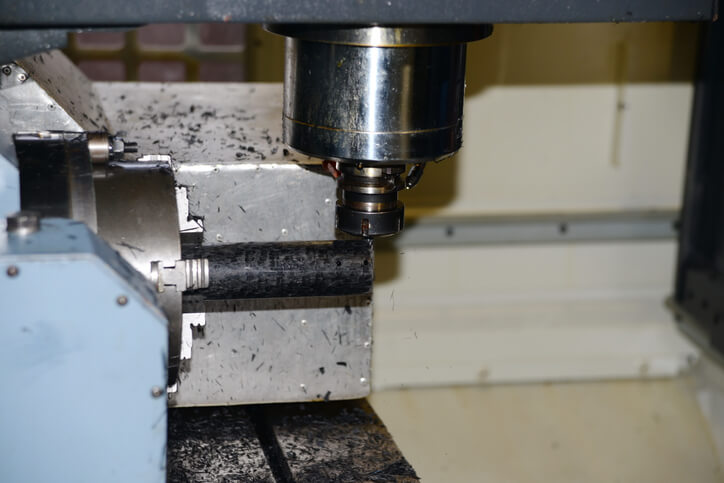

How 3-Axis Vertical Milling Services Work

In 3-axis milling, the cutting tool moves along three linear axes: X (horizontal), Y (vertical), and Z (depth). This straightforward approach makes it ideal for projects requiring vertical milling services, such as creating flat surfaces, slots, and basic contours. When machining materials like brass or aluminum, 3-axis milling provides reliable results for straightforward geometries.

Key Advantages of 3-Axis Milling

1. Cost-Effective Solution

For many manufacturers, 3-axis milling offers an economical choice without compromising quality. The simpler machine configuration and widespread availability of skilled operators help keep costs manageable, especially for brass milling and basic aluminum milling service projects.

2. Faster Production for Simple Components

When manufacturing straightforward parts, 3-axis machines often complete jobs more quickly than their 5-axis counterparts. This efficiency makes them particularly valuable for high-volume production runs of simple components.

3. Wide Availability and Accessibility

The prevalence of 3-axis machines in the industry means greater availability and typically shorter lead times. This accessibility makes it easier to find qualified suppliers for your custom CNC milling needs, whether you’re producing military enclosures or standard industrial components.

Understanding the Limitations

Complex Setup Requirements

While 3-axis milling excels at simple geometries, complex parts often require multiple setups. Each repositioning of the workpiece introduces potential for error and increases production time. For instance, manufacturing intricate military enclosures might require several setups to achieve all necessary features.

Geometric Constraints

3-axis machines cannot easily create undercuts or machine complex contours in a single setup. This limitation particularly affects projects requiring:

- Angled holes or channels

- Curved surfaces on multiple faces

- Deep pockets with complex internal features

- Complicated contours common in aerospace components

For manufacturers considering their options in vertical milling services, these limitations often influence the decision between 3-axis and 5-axis solutions, especially when working with materials like aluminum or brass that require precise machining.

Overview of 5 Axis Milling

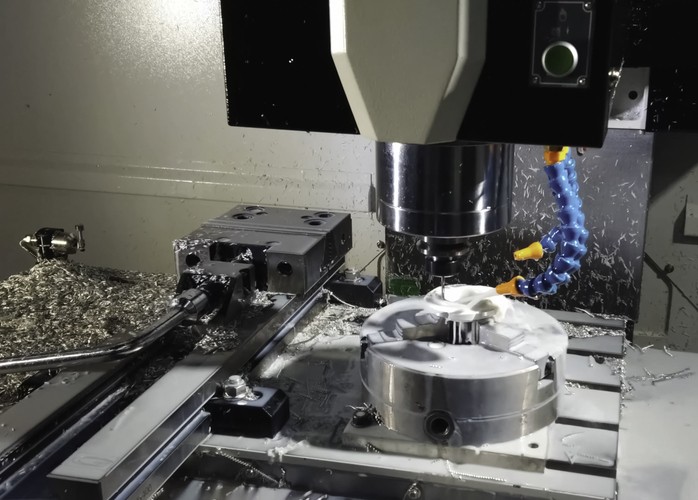

Understanding 5-Axis CNC Milling Technology

5-axis milling represents the cutting edge of precision fabrication, adding rotary and tilting movements to the three linear axes. This advanced capability allows the cutting tool to approach the workpiece from virtually any angle, revolutionizing how manufacturers approach custom CNC milling projects. For companies specializing in vertical milling services, 5-axis technology opens new possibilities for creating complex components.

Key Advantages of 5-Axis Machining

Enhanced Single-Setup Capabilities

Unlike traditional 3-axis methods, 5-axis milling can complete intricate parts in a single setup. This capability proves invaluable when manufacturing military enclosures or aerospace components that require precise, complex geometries. The elimination of multiple setups improves accuracy and significantly reduces the potential for human error.

Superior Complex Geometry Handling

5-axis technology excels at creating:

- Sophisticated curved surfaces

- Deep cavities with compound angles

- Intricate undercuts and channels

- Complex contoured surfaces

This versatility makes it particularly valuable for precision fabrication of challenging components that would be difficult or impossible to produce with 3-axis equipment.

Reduced Production Time for Complex Parts

While the hourly rate for 5-axis machining may be higher, the ability to complete complex parts in a single setup often results in shorter overall lead times. This efficiency becomes particularly apparent when manufacturing components that would require multiple setups on a 3-axis machine.

Understanding the Limitations

Higher Operating Costs

The sophisticated technology behind 5-axis machines results in higher hourly rates compared to 3 axis vs. 5 axis milling options. This cost difference makes it essential to evaluate whether the additional capabilities justify the investment for your specific project.

Limited Availability

Fewer machine shops offer 5-axis capabilities due to:

- Higher equipment investment costs

- Need for specialized operator training

- Advanced programming requirements

Excessive for Simple Projects

Using 5-axis machinery for basic parts that could be efficiently produced with 3-axis equipment may unnecessarily increase costs without adding value.

Material Considerations in Milling Selection

Versatility Across Materials

Both 3-axis and 5-axis machines effectively handle a wide range of materials, making them suitable for various applications in aluminum milling service and brass milling projects. The choice between them frequently depends more on part geometry than material selection.

Common materials processed by both methods include:

- Aluminum alloys for aerospace components

- Brass for precision electrical components

- Engineering plastics for prototypes

- Carbon fiber composites

- Various grades of steel

- Specialty alloys

5-Axis Excellence with Challenging Materials

5-axis technology particularly shines when working with difficult-to-machine materials, offering:

- Optimized tool angles for better cutting efficiency

- Improved chip evacuation

- Enhanced coolant delivery

- Better surface finish on complex parts

This superiority becomes especially evident when performing brass milling operations on intricate components or working with tough aerospace alloys. The ability to maintain constant tool engagement and optimize cutting angles helps extend tool life and improve surface quality, particularly important for high-value materials.

Industry Applications and Use Cases

Understanding where each milling technology excels helps inform the choice between 3 axis vs. 5 axis milling for your specific application. Let’s explore how different industries leverage these technologies for optimal results.

Optimal 3-Axis Applications

Versatile Production Across Industries

3-axis milling remains the go-to choice for many manufacturing scenarios, particularly excelling in:

- Standard component production

- Flat surface machining

- Basic geometric shapes

- Pattern repetition work

High-Volume Manufacturing

When it comes to the metal fabrication process for simpler components, 3-axis machines offer distinct advantages:

- Faster cycle times for basic geometries

- Lower per-part costs

- Simplified programming requirements

- Efficient material handling

Prototype Development

For basic prototype machining services, 3-axis milling provides:

- Quick turnaround times

- Cost-effective solutions

- Straightforward design validation

- Easy modifications for iterative development

5-Axis Milling Applications

Aerospace and Defense Industry

The aerospace sector particularly benefits from 5-axis capabilities when manufacturing:

- Complex turbine components

- Structural aircraft parts

- Military enclosures with precise specifications

- Navigation system housings

Medical Device Manufacturing

5-axis precision proves invaluable for:

- Surgical instruments

- Implant components

- Medical device housings

- Custom prosthetic parts

Automotive Applications

The automotive industry utilizes 5-axis milling for:

- Engine components

- Custom performance parts

- Prototype development

- Tool and die manufacturing

Military and Defense Components

Beyond standard military enclosures, 5-axis excels in creating:

- Communication equipment housing

- Tactical equipment components

- Precision weapon parts

- Specialized electronic enclosures

Oil and Gas Equipment

The energy sector relies on 5-axis precision for:

- Valve components

- Pressure vessel parts

- Subsea equipment

- Custom fittings and connectors

Advanced Consumer Products

Complex consumer goods benefit from 5-axis capabilities in:

- High-end electronics housing

- Luxury product components

- Custom sporting equipment

- Specialized tools

Making the Right Choice: 3-Axis or 5-Axis?

Evaluating Part Geometry

The complexity of your part often determines the most suitable metal fabrication process:

- Simple, prismatic shapes typically suit 3-axis milling

- Complex contours and angles usually require 5-axis capabilities

- Consider future design modifications

- Evaluate all part features comprehensively

Assessing Precision Requirements

Your precision needs significantly influence technology selection:

- Standard tolerances often suit 3-axis capabilities

- Tight tolerances may benefit from 5-axis precision

- Consider surface finish requirements

- Evaluate geometric dimensioning and tolerating needs

Production Volume Considerations

Volume requirements affect the economics of your choice:

- High-volume simple parts typically favor 3-axis

- Complex parts may be more economical on 5-axis despite higher hourly rates

- Consider batch sizes and repeat orders

- Evaluate total production lifecycle costs

Partner with Experienced Providers

Consulting with experienced rapid prototype machining and production experts helps ensure optimal technology selection:

- Discuss your specific requirements

- Review material considerations

- Evaluate cost implications

- Consider lead time requirements

The choice between 3 axis vs. 5 axis milling ultimately depends on your specific needs, but working with an experienced partner who offers both capabilities ensures you’ll get the most appropriate solution for your project. They can help evaluate your requirements and recommend the most efficient and cost-effective approach for your specific application.

Making the Right Choice for Your Manufacturing Needs

When evaluating 3 axis vs. 5 axis milling for your next project, it’s crucial to understand that both technologies continue to serve vital roles in modern manufacturing. While 3-axis milling remains the backbone of high volume CNC machining, offering cost-effective solutions for straightforward components, 5-axis technology provides distinct advantages for complex projects requiring enhanced precision and single-setup capabilities.

As one of the leading metal fabrication companies in the industry, NAMF maintains expertise in both technologies to ensure our clients receive the most appropriate solution for their specific manufacturing requirements.

Let our team of experts help determine the best custom CNC milling approach for your project. Request a quote today to experience the NAMF difference.